Quality is our signature

A commitment to quality, detail, and consistency since day one.

Our founders Joan & Owen Maxwell started Regulator in an abandoned A&P Grocery Store in Edenton, North Carolina, when they were just 28 and 30 years old. As avid boaters and anglers themselves, they wanted to build a center console boat that exceeded all expectations.

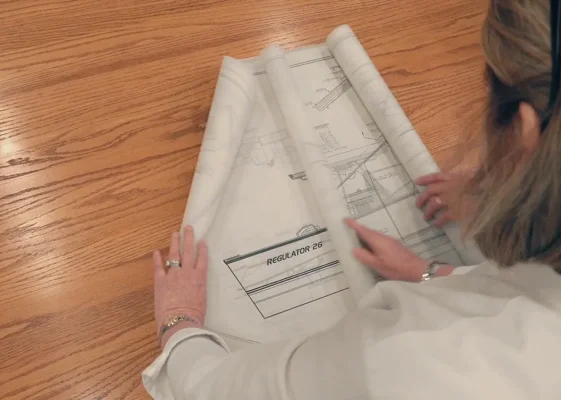

So day after day, and night after night, they built a full-scale model of the first Regulator 26 by hand, personally testing and tweaking every little detail until they knew it was right. This was the beginning of a commitment to detail and consistency that continues today with an incredible team of experts in our state-of-the-art manufacturing facility in Edenton…just down the street from the old A&P.

Our

Craftsmanship

Our talented team of engineers and expert boat builders execute every step of the build in meticulous detail to handcraft the Regulator you deserve.

Quality isn’t just about one thing—it’s the space where design, functionality, and durability come together. The tests we run, the processes we maintain, and the enhancements we make are made with purpose. This approach means that when we integrate new features, we do it without compromise. And we never sacrifice the fit, finish and ride that make a Regulator, a Regulator.

OUR MISSION

We build the best center console sportfishing boats with people, processes and resources to honor God.

OUR VISION

To expand Regulator while investing in a bright future for our team and community.

OUR VALUES

SAFETY

We follow all safety policies and procedures.

INTEGRITY

Doing what is right before God regardless of the consequences.

PERSONAL ACCOUNTABILITY

I do what I say I will do. I take ownership of my role and my future.

STEWARDSHIP

It all belongs to God.

Our

Story

1988

Reinventing the Deep Vee Center Console

Joan & Owen Maxwell set out to prove that you can have it all, building the first full scale model in an abandoned A&P grocery store.

1990-1991

Making a Splash

The first-ever iconic Regulator 26 launches and is named the best up-and-coming center console by Sport Fishing Magazine.

2003

Excellent Customer Service Awarded

Regulator receives the company’s first Customer Service Index Award, launching a tradition of recognition for the highest level of customer service.

2012

Transatlantic Voyage of the Queen Bee

The Regulator “Queen Bee” is discovered off the coast of Spain after an unmanned three-and-a-half year 3,000-plus-mile journey across the Atlantic – with little more than slightly-bruised T-Top frame, and every part still intact.

2019

XO Series of Crossover Center Consoles Launches

Regulator introduces the versatile XO Series of center console hybrid boats for easy access to lakes, bays, and skinny waters.

2019

55,000 sq ft Factory Expansion

To keep up with demand and fuel growth, we grew our factory footprint..with additional plans in the works!

TOUR THE FACTORY

While we’ve ensured innovation and evolution at every turn, the most important elements of Regulator have remained the same. We still build each of our boats by hand. We still have an unwavering commitment to consistency in every build. And we still place quality before delivery to ensure that you are getting the boat you deserve to enjoy the Offshore Life™ and keep your friends and family safe in any waters.

2024 Factory Tour Teaser

1:08 MIN

WORKING AT

REGULATOR

We build great boats and have fun doing it!

We are proud to be known for our commitment to quality boat building, but the heart of Regulator is our dedication to our team members. We welcome you to explore our company culture and career opportunities.

© Copyright Regulator Marine, Inc. All Rights Reserved. Specifications, standards, options and availability are subject to change.

Regulator Marine and the Regulator Marine fish logo are registered trademarks of Regulator Marine, Inc.