Tour the Regulator Factory with Boats.com

By Team Regulator/ November 12, 2025

SHARE

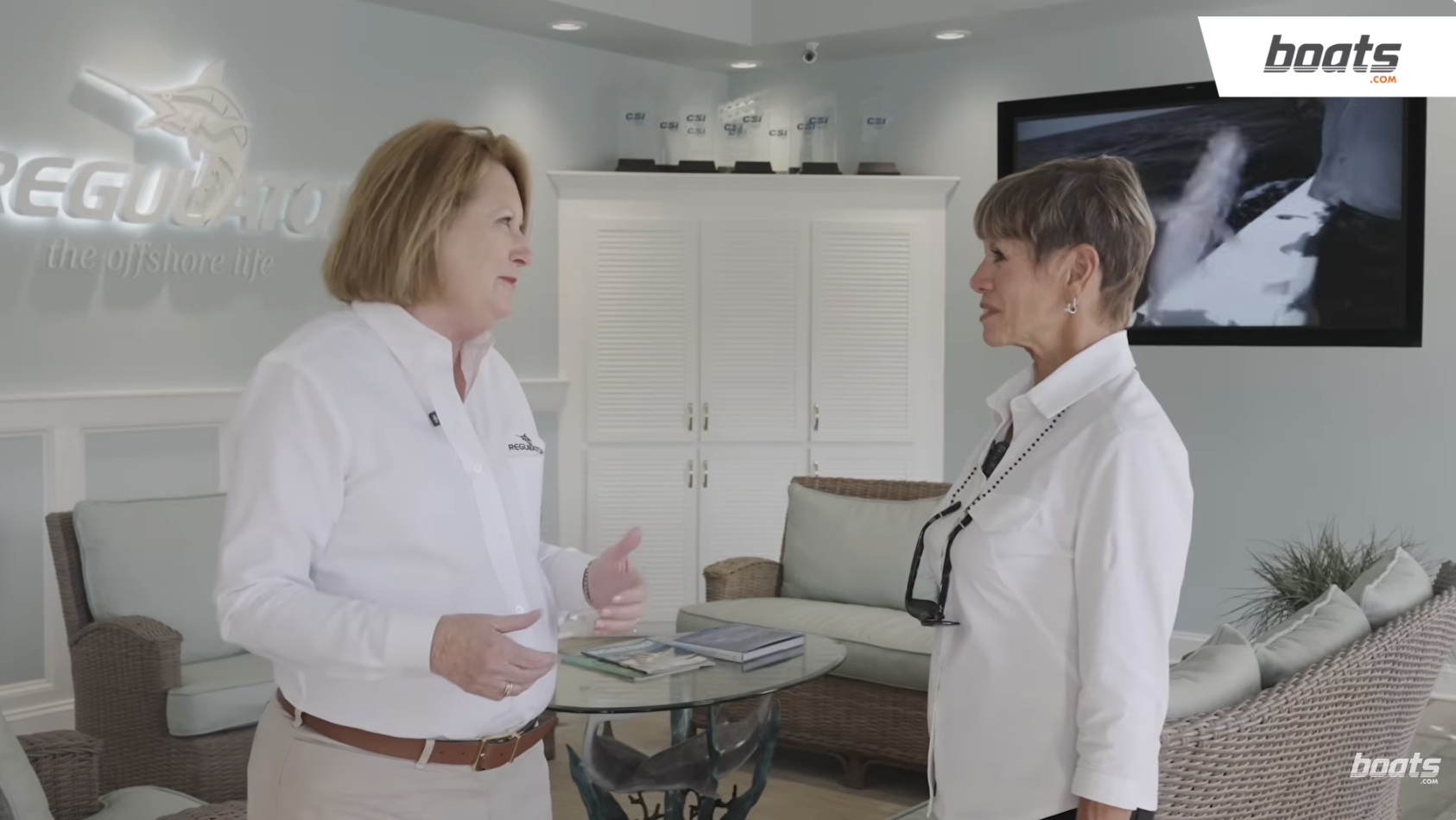

Boats.com visited the Regulator factory to see how our Legendary Ride is made.

Read on or...

[Intro – Marilyn from boats.com]

Factory Fridays from boats.com — the show where we visit builders across America to get a firsthand look at their boat-building techniques, materials, and stories.

Marilyn: Well, Joan, it's a pleasure to be here at Regulator. Thanks so much for having us.

Joan Maxwell (President & Co-Founder, Regulator Marine): We are so excited that you're here, Marilyn. It's always a privilege to open this factory up and show people what we do here because what we do is pretty special.

Marilyn: And also, how long you've been doing it! Now, you said you started in this location in 1980 with your first boat, the 26 Classic, right?

Joan: In 1988, we were in an old A&P grocery store here in town, and then we moved into this facility in 1990. We've been growing it out through the years.

Marilyn: Like 100% growth out!

Joan: Yeah, there's been a lot of growth out — starting here at 13,200 square feet. And you walk around today, it looks a lot different, as you'll see when we take you on the tour.

Marilyn: So, it's nice that you have a lot of property here to expand in this beautiful town of Edenton.

Joan: Yes, it is an amazing town, and we do have property to expand both here and across the street where our wiring harness shop is located.

Marilyn: Well, we're eager to see how you develop the Regulator ride.

Joan: So, the Regulator ride is all about who we are. We started with the 26, which you mentioned, and that boat was deep-V. It was innovative in its time — things like a fiberglass stringer system and a head in the console, which we all take for granted these days. Those were innovative things at the time.

Today, we're working on all kinds of innovative things, and you'll see some of those when you come through the plant and meet some of our engineers. Our mission here is to build the best center console sportfishing boats with people, processes, and resources to honor God. We get the privilege to do that every single day. So, when somebody comes through here, it's like, wow, this is a gift to us that we get to share what we do.

Marilyn: Well, and that's got to build trust in your consumer base as well because people know that you're going to do right by them.

Joan: And that's what we're going to see here at Regulator today.

Marilyn: That's exactly what you're going to see. And more importantly than our processes, I'm excited for you to see the people — because the people are what drive this business. They understand the importance of doing it well and doing it for the people that God sends us.

Marilyn: Well, we're eager to see the factory. Joan, where are we going to start?

Joan: We're going to start back around the CNC area with Keith Ammon. So, I'm going to turn you over to Keith for a great tour.

Marilyn: All right. Thanks so much.

Joan: You're welcome. We'll look forward to seeing you when you finish up.

CNC & Core Station

Marilyn: All right, Keith, where are we now?

Keith Ammons (VP Sales and Marketing at Regulator Marine): We're in our fiberglass prep area and core station. You'll notice there's a 3D router, a 2D router around the corner, and a big glass-cutting table. This is where we're getting all of our core material ready to go.

Marilyn: Well, I can see why Regulator is on the cutting edge. So, show us how this works.

Keith: I’ve got a couple of examples right here. You can feel this lightweight foam piece that we’ll cut out to go somewhere into the boat. Here’s a piece of ABS plastic that would go with this exotic cut around this piece of aqua steel. You feel how heavy that is? What I can tell you is there are 52 different core materials that we use in our boats. There’s a naval architect involved in every step, making sure that everywhere there’s a screw or bolt or connection, we have strength behind it.

Marilyn: So, it’s the appropriate material for the appropriate piece that’s being attached to it.

Keith: Exactly. You ready to go see that big old puzzle put together?

Marilyn: All right, let’s head back to lamination.

Lamination

Keith: So, here we are in parts and supply. This is the supply room, and we’re going to lead right into lamination. One of the people I’d like you to meet, Marilyn, is Don Seal. He’s an engineer and he can explain how all those big parts come together.

Marilyn: Don, nice to meet you.

Don Seal (Engineer): Nice to meet you, too.

Marilyn: I hear that you’re the man that can explain to me about the Regulator ride.

Don: I’ll try. This is the part of the process we don’t want to change — the part of our legacy. We’re constantly innovating, but this is stuff we don’t want to change.

So, this is our newest boat, the 35 Regulator, and it’s on day three. We build the bottom specifically for strength. We core the sides to give rigidity without adding a lot of weight. We want weight down low to keep our center of gravity low — it makes the boat feel more stable.

Marilyn: It looks like you grind between your layers there.

Don: We do. We’re making sure the next layer bonds correctly to the layer underneath. We call it increasing its surface energy — we’re just grinding it so the resin and cloth actually bite to the layer underneath.

Marilyn: When you have your skeleton core that you’re going to place into the boat, when does that happen in the process?

Don: That happens on the last day. The stringer will get built, rigged, and bonded so that the grid and the hull become one — acting as one piece, not two.

Marilyn: Will we see the stringer system also?

Don: Yes, ma’am. We got one right down there that I can show you.

This is large parts lamination. All the major parts — liner, deck, and stringer — are made here. Notice how deep the stringers are. We want tall ones because they resist bending. This will be covered with structural glass before it’s finished. It has to be strong enough to distribute all the loads throughout the boat.

Innovation in lamination isn’t something the customer sees, but we do it. For instance, we found it more efficient to put in bulkheads after making the stringers. We pre-build infused bulkheads and mount fixtures on them. When it’s time to install, we index and bolt them down precisely.

That’s where the Regulator ride comes from — putting the weight in the right place and making sure the structure is strong enough to support the hulls.

Finishing, Wiring & Assembly

Keith: From here, we’ll head over to finishing. There are a few folks you should meet who’ve been here a long time.

Marilyn: Great, let’s go.

[At Finishing Station]

Keith: This is Jerel Sharp. Jerel’s been with us for years.

Jerel Sharp (Finishing Supervisor): Every morning, we start our day with prayer. We pray for safety, for each other, for the work we’re about to do. It really sets the tone. We’re like family here — we look out for one another.

Keith: And here’s Tony Gibbs, who helps lead our “In His Service” program.

Tony Gibbs (Employee Services): We tithe 10% of proceeds to charity and also focus on taking care of our people — physically, mentally, and spiritually. We want everyone here to know they’re supported beyond the job.

[At Wiring Station]

Keith: Andrew, can you show Marilyn what you’re working on?

Andrew (Electrical Technician): Sure! Every wire is labeled, documented, and tested before it ever goes into a boat. That way, if you have an electrical issue 10 years from now, we know exactly which wire it is and where it goes. It’s all about reliability.

Final Assembly

Don: Now, here’s the assembly shop. This is where hulls, liners, and decks are bonded together, and where we rig the engines. We partner closely with Yamaha to make sure every system is perfectly tuned before delivery.

Marilyn: Everything looks so precise — even down to the smallest details.

Don: Exactly. Every hole, every bolt, every sealant bead — it’s all tracked and inspected.

[Prefab Station]

Keith: Here’s where the consoles are built and pre-rigged. Doing it here gives us consistency and quality control before installation.

Closing

Marilyn: Before we wrap up, I wanted to meet one more person I’ve heard about — Marcy Barnes.

Marcy Barnes (Assembly Technician): Hi, Marilyn! I actually went through the boat-building program at the local community college and started here 17 years ago. I’ve learned everything from lamination to assembly. Regulator’s like home — we take pride in what we build and who we build it with.

Marilyn: That’s incredible. You can feel the care and purpose in every corner of this place.

Joan: That’s what makes Regulator what it is — craftsmanship, innovation, and faith. We’re blessed to do what we do, and we’re grateful for everyone who’s part of it.

Marilyn: Thanks so much, Joan — and thanks to the whole Regulator team. What an amazing look behind the scenes at one of the finest center console builders in America.

SHARE

About Author

Team Regulator

Our team is regularly working on the best stories, videos and how-to articles to help you learn more about Regulator center console boats and make the most of your boating and fishing experiences. Have an idea for a story? Drop us a line via the Contact Page.

Regulator 25 Returns

The 25 has great performance…a quick and solid boat with twin 250s. Let’s take you inside the belly as we start the assembly process.

Regulator 23: How It’s Made

Why is the ride so solid? Why are the rod holders so strong? What makes this fit & finish so clean? Take a look behind the scenes of the Regulator 23 build to find out…

GET GREAT CONTENT IN YOUR INBOX

Model year updates, insider events, and first looks at sales promos, gear drops and more.

Come see for yourself

Take a

factory tour

See how we build every inch of every Regulator to meet your every need.

© Copyright Regulator Marine, Inc. All Rights Reserved. Specifications, standards, options and availability are subject to change.

Regulator Marine and the Regulator Marine fish logo are registered trademarks of Regulator Marine, Inc.